Keeping the precious for you

Keeping the precious for you

Main / Used technologies

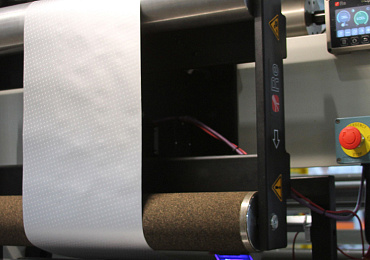

Varnishing

In our production, we apply a primer and thermal varnish to the foil, which is then used for soldering to plastic containers. After passing the entrance inspection, the roll is installed on the varnishing line. It goes through sections where the primer is applied and drying chambers. Then, thermal varnish is applied, and the material goes through the drying chambers again. Finally, the foil is wound into rolls, resulting in semi-finished product for finished packaging.

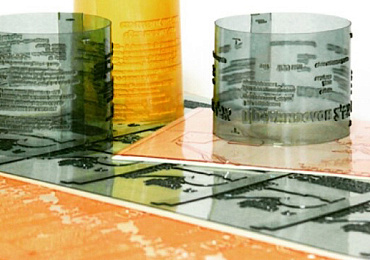

Flexoprint

We apply paints to the foil to create a unique design for packaging. Our archive contains over 3,000 design options.

All printing machines in our production are flexographic. The features of flexography are constantly improving: the print quality is getting better, and the speed of replacing circulation is increasing. This type of printing is also very economical.

We use two types of paints: UV-curable and solvent. Both types are certified for food packaging.

Embossing and die-cutting

First, the foil with the seal is pressed on the cutting press. This process gives the foil rigidity and makes it easier to separate the plates in the filling equipment. We offer three types of embossing patterns: "worm", "needles”, and "linen". You can also order a package with your own logo.

After embossing, the plate cover is cut down using a press. Both embossing and die-cutting processes are performed in a single pass of the material through the machine. At this stage, the rolled products become the final packaging – the plates.

The quality of our products is monitored at every stage of production.

Profitroll

This is an alternative to the standard plate. The key difference is flexibility. PROFITROLL is rolled up rather than folded.

PROFITROLL offers the following advantages:

• Savings on product launch — starting from $20,000.

• Reduced operating costs.

• Perfect color reproduction.

• Disinfection capability.

Digital printing

This type of printing enhances the appearance of packaging and adds value to products, even in small and medium-sized print runs, thanks to advanced equipment.

Preparing layouts in a graphic studio

Before being sent to circulation, all layouts are prepared in a dedicated graphic studio. The use of specialized software and regular color profiling helps to achieve the maximum effect and minimize environmental impact.

Unilid

The technology behind Unilid is based on the ability to connect PET film with foil and then remove it. This allows you to open the container and consume the product in portions without worrying about spilling it.

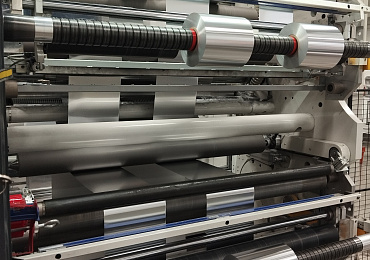

Lamination

Lamination is a technology that enables the combination of various materials to create new ones. For instance, this is how ALU-PET and ALU-PET-ALU are formed.

Cutting aluminum foil

Digital marking

Own Laboratory

Smooth Platinum

14.05.2024

08.05.2024

07.05.2024

04.04.2024

Still

have questions?

Leave a request, our specialist will contact you and we will answer all your questions in detail

Fill out the form, we will call you back shortly